Products Description

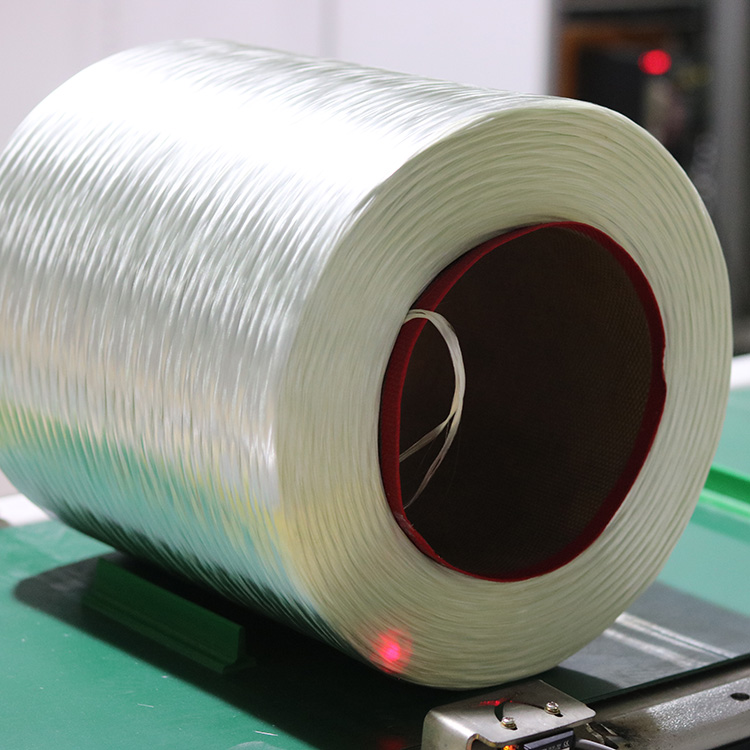

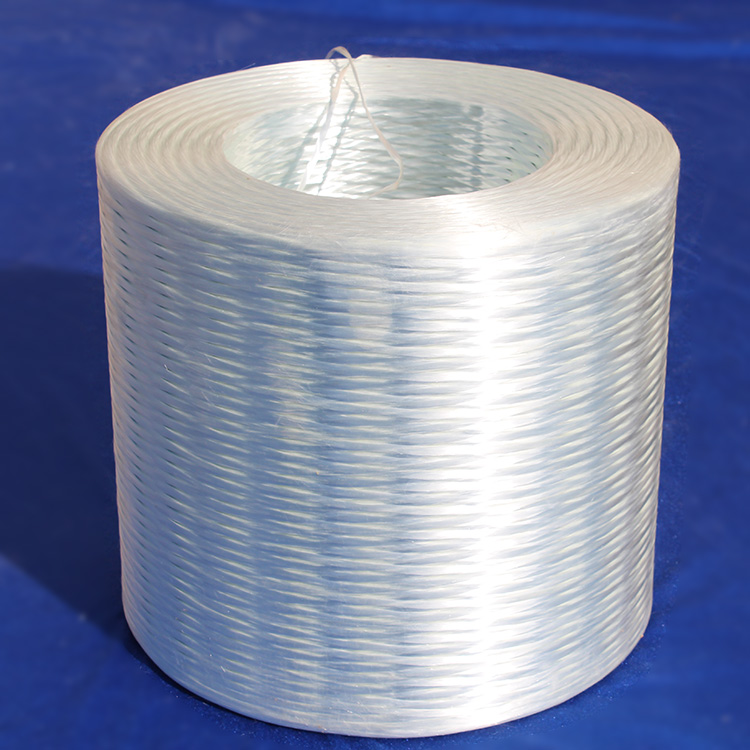

E-glass fiberglass direct roving is one kind of continuous roving which is winded by certain number of filaments directly.

For winding, pultrusion, weaving, profile, and glass fiber cloth manufacturing.

Product Features

With silane type coupling agent, high mechanical strength after being made into composite material.

Excellent permeability.

Concentration performance and taxability.

Good wear resistance, low fuzz during the using process, easy to weave or process.

Suitable for reinforcement of various matrix resins.

Suitable for a variety of application processes.

Packaging

Direct roving is packed in plastic bag or film,and then is packed on pallet.

The weight of each roll is 16 to 20 kgs. Each pallet stacks 48 rolls(3 layers) or 64 rolls(4 layers).

The pallet measurement is 1.1×1.1×0.95m and 1.1×1.1×1.2 m.

Storage

Products should be stored in a dry and cool place.

Try to keep the packing intact before use.

Pallets should not be stacked over 2 layers and cartons not over 4 layers.

The storage period is recommended for no more than 12 months.

Application

Suitable for FRP winding, pultrusion products (such as FRP pipes, pultrusion profiles, storage tanks, etc.) and other fiberglass products (such as fiberglass geogrid, roving, etc.).